Current idea dump

Posted: Jan 18, 2026

This blog will just be a bit of a dumping ground for all the various ideas I’ve had floating around in my head for this project. I’m not sure if any of this will make it into the final version but I figured i’d document it all anyway to see the process and how the plan evolves.

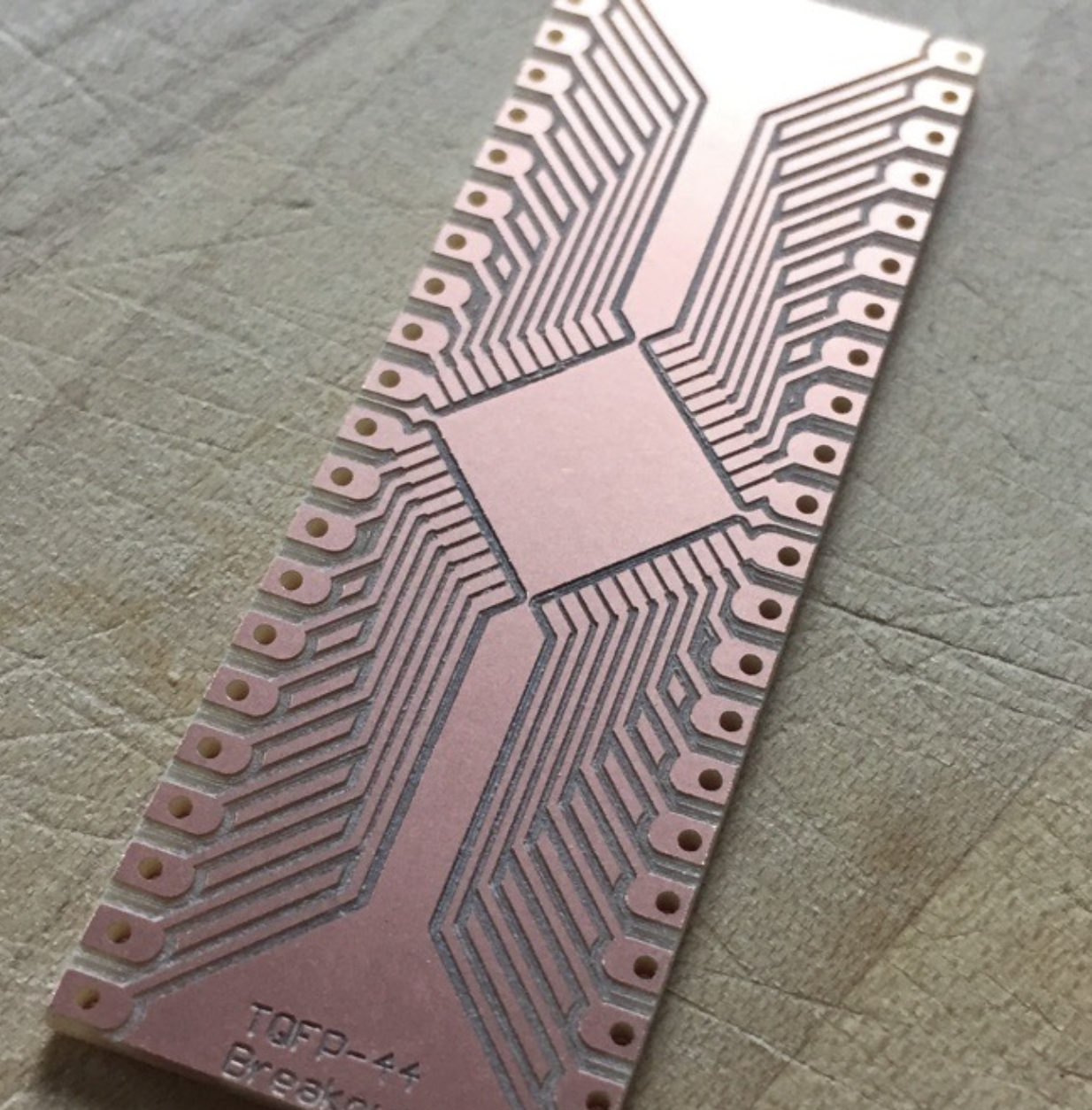

PCBs

I’ve been “building” a MPCNC CNC Router on and off over the last few years that I’ve never gotten around to finishing - so my first idea has been to finish that and use it to mill some basic PCBs. A PCB size of around 200x200mm should suffice for what I’ll need to fit, I’ll work that out on the first iteration of the ALU board whenI get around to making it.

The other option on the table is ordering PCBs from a place like JLCPCB. Even then the cost is still significantly higher than producing it yourself - something in the magnitude of ~$45 for 5 PCBs (minimum order per design) plus another ~$40 for shipping. Say I make 6 different PCBs thats getting up around the $500 dollar mark - whereas the DIY CNC’d boards would only be the ~$80 or so for the blank copper clad boards - a big saving (not to mention the high likelihood of me messing something up on the PCB design and having to scrap a board or two). I guess I’ll have to get the CNC router finished and see what kind of quality PCBs I can produce and see which direction I want to go.

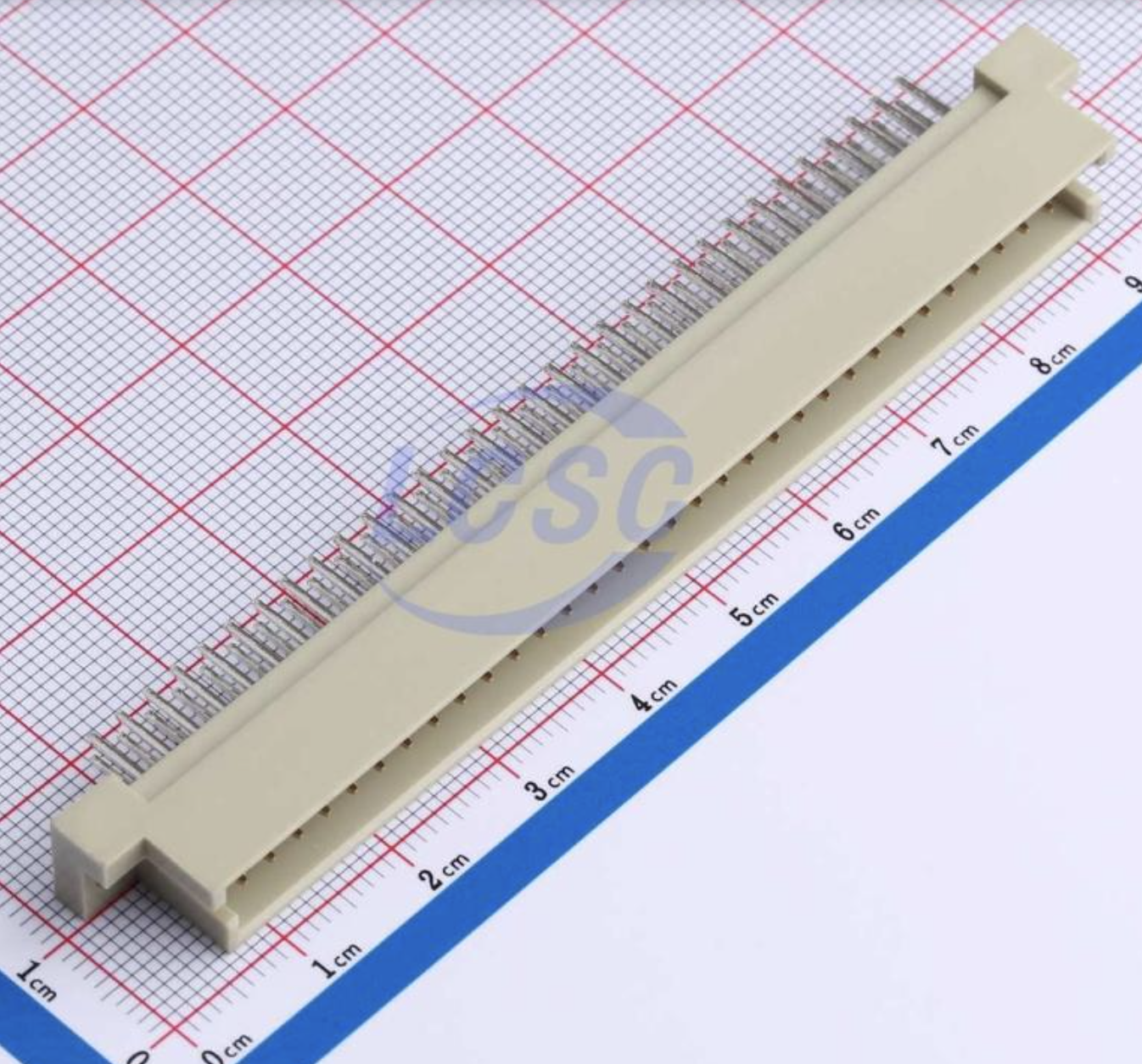

Backplane

I’ve not really started any of the proper design work, but I found these 32x2 backplane connectors over on LCSC. I figured since I’m only using two layer PCBs (most likely), if I bridge the two rows that’ll gives me 32 backplane connections per connector and eliminates the difficulty getting to the rear set of connections. I’ll have the option to fit two per board if I need more than the 32 connections - 64 should be plenty.

Assembler app

I’m also planning write a simple .NET WinForms app for the assembler that takes the assembly style code (more on that in a future post) and converts it to the encoded bytecode and prints it onto the receipt paper using a thermal receipt printer.

Paper Tape “punchcard” reader

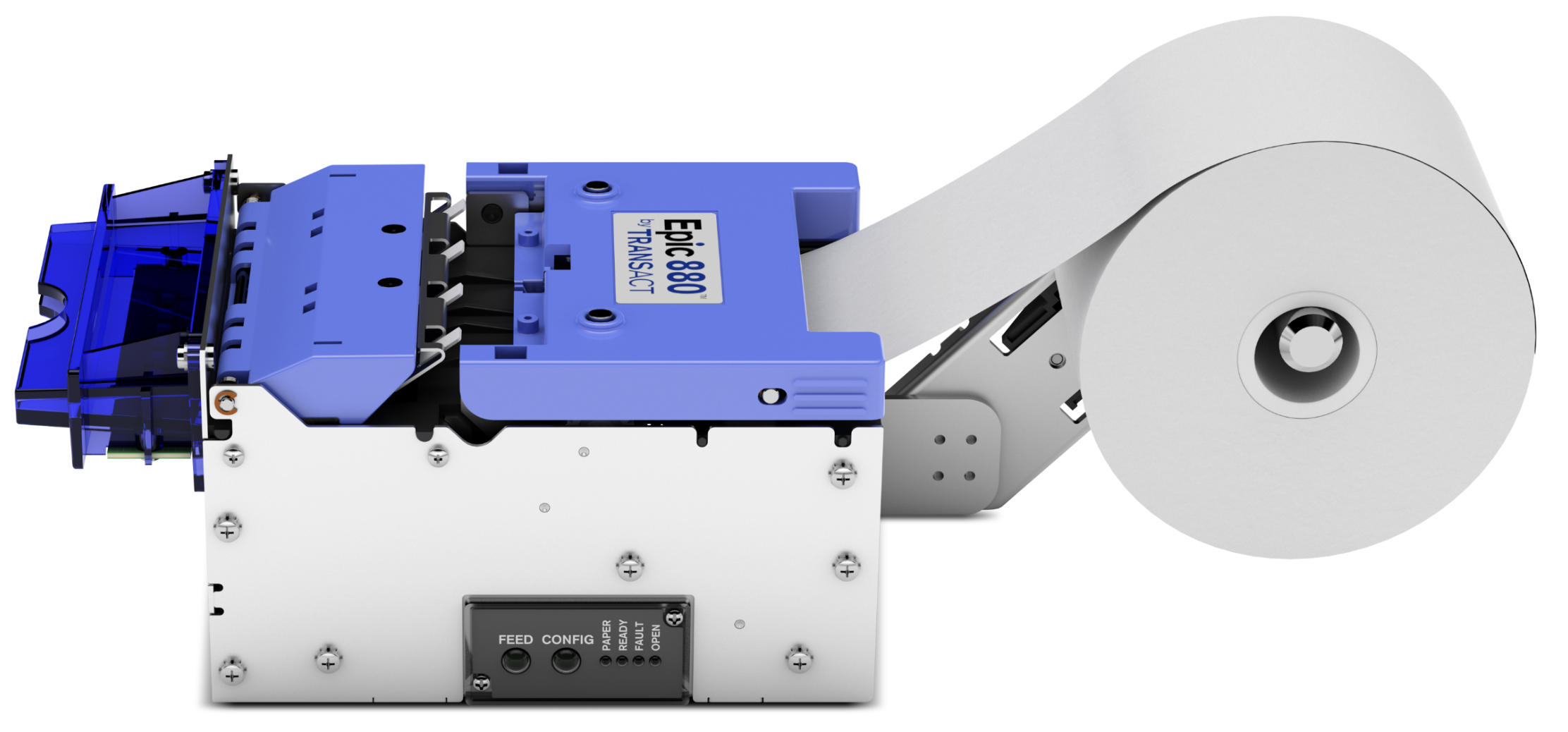

As I mentioned over on the first Architecture post, I came across some thermal receipt printers that we’re being e-wasted at work.

The plan here will be to modify one of these printers to use as a “tape reader” feeding the printed program into the machine using its rollers and stepper motors and through a reading “head” using an array of LDRs connected up to an Arduino.

Display

I haven’t come up with much of a plan for this as yet - Something along the lines of mapping some of the memory to an LED matrix for basic display functionality will do for now.